For a sustainable future, we must have

RESPECT FOR THE PLANET

Establishing a Recycling-based Society

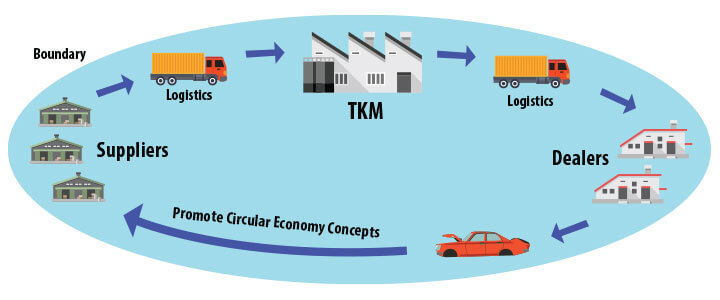

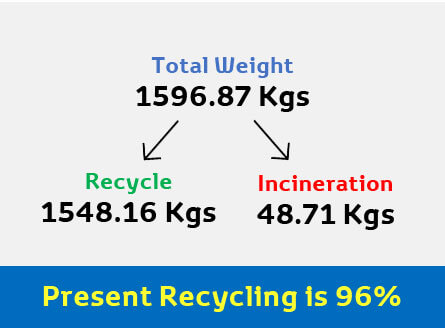

Promoting recycling at every step ensures resource conservation, optimization and efficient management throughout our value chain. This helps us as a springboard to create large-scale change.

Our Approach

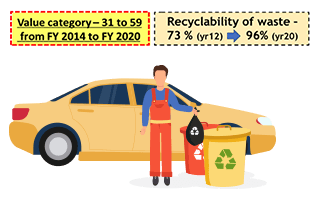

A. TKM Waste Management System Value management System

B. Expanding to Value Chain

Create consciousness across value chain on waste to value management

C. Waste Management Circular Economy

Our Approach

End of life vehicle Management

TKM Pilot End of Life Vehicle (ELV) facility has been established at the premise.

TMC / TDEM has Recognized TKM facility as MODEL FACILITY under Toyota Global 100 Dismantlers Project

Hazardous Waste Reduction

TKM’s ultimate goal in this regard is to send zero hazardous waste to the landfill.

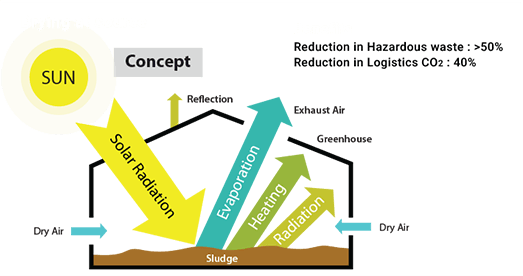

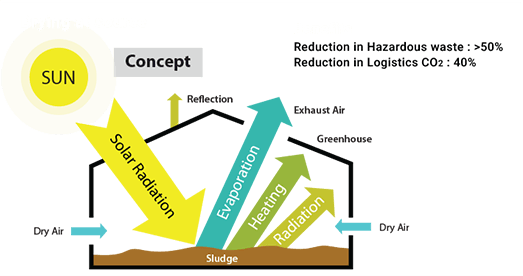

Towards the same, TKM has established Sludge Drying Yard for managing hazardous waste, that works on the concept of Green House Effect.

It has also established Composting Yard, where Bio-sludge gets composted that is then used for plantation inside the campus.

About 4% of Waste is sent to incineration and co-processing.

Key Highlights:

- From the year 2014 to 2020, about 1,50,627 tons CO2 Emissions has been reduced.

- TKM is successfully Minimizing environment impact by eliminating 2850 tons of Hazardous waste to Landfill.

Chemical, Phosphate & Paint Sludge

TKM with ACC cements carried out first trials of Co-processing Involving MOEFCC,CPCB,KSPCB (Yr 2008)

BIO Sludge